For precise dosing, efficient processing and reliable results.

Systems and Dosing Technology.

Dispensing systems from LOCTITE

Reliable technology for accurate and reproducible dosing

The dispensing systems from LOCTITE are the perfect solution for the precise application of adhesives, sealants, and other liquid media. Whether in mass production or in demanding individual applications – LOCTITE dispensing systems ensure consistently high quality, clean processing, and maximum efficiency. With programmable settings, automatic control, and optimal process control, even the smallest quantities can be dispensed accurately and applied flawlessly.

Manual Hand Dispenser

For precise dosing in small series and in craftsmanship

Our manual hand dispensers enable precise and controlled application of adhesives and sealants directly from the cartridge or syringe. Whether for spot applications, fine lines, or small pours – the ergonomic devices offer maximum control and prevent material loss as well as uneven application. Ideal for workshops, repair work, prototype construction, or small series production.

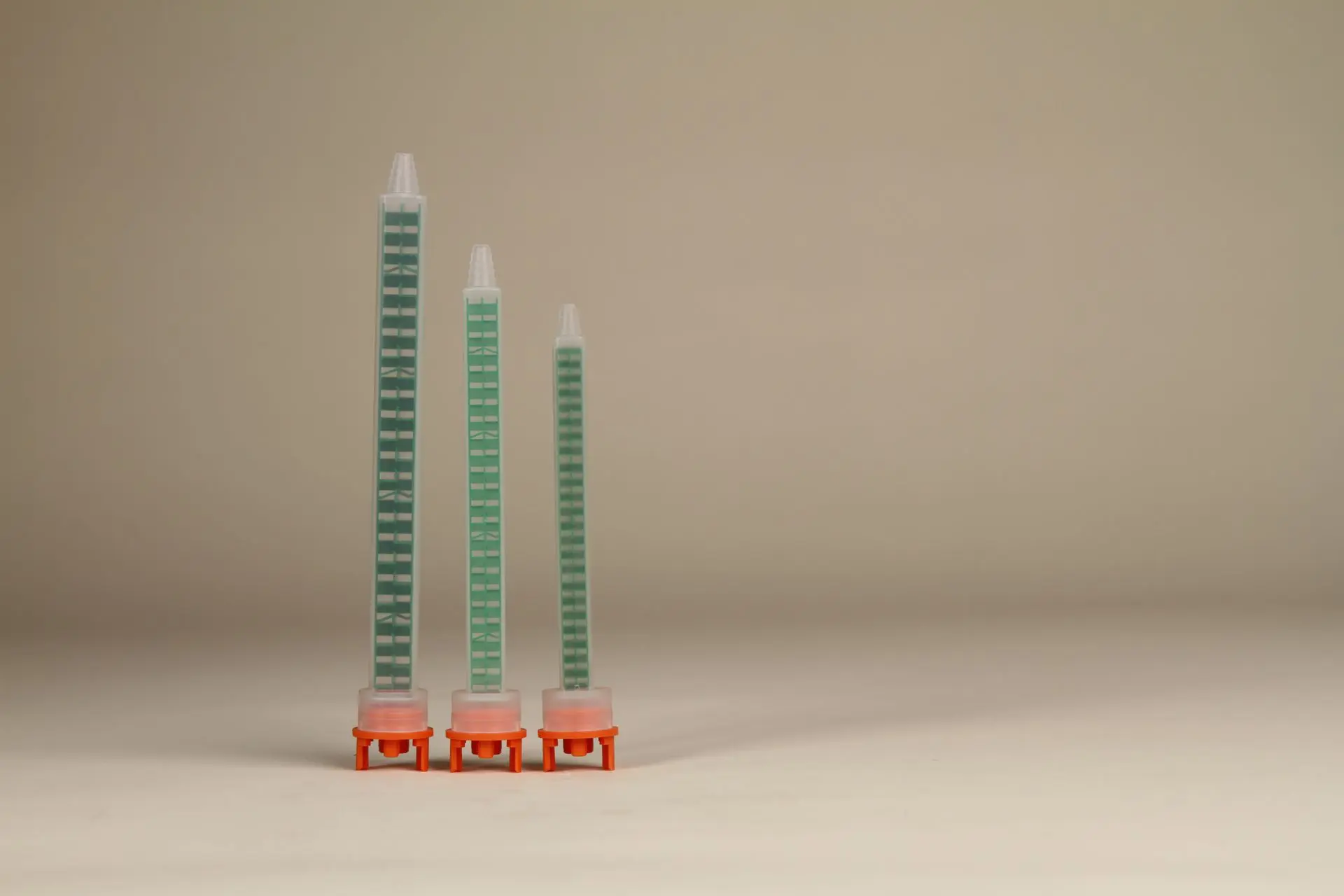

Accessories for dosing technology

Mixing nozzles, needles, cartridges and more

With the right accessories, you achieve optimal application results. We offer a comprehensive range of high-quality mixing nozzles, static mixers, needles, cartridges, adapters, and venting accessories for all common dispensing systems. This ensures consistently precise processing of your materials and reduces downtime through perfectly matched components.

LOCTITE UV curing chambers

Professional solutions for controlled UV curing

LOCTITE UV curing chambers provide an efficient and reliable solution for the curing of UV-curable adhesives and coatings. With uniform light distribution, precise control of exposure time, and integrated safety technology, they ensure reproducible results and the highest process reliability. Ideal for laboratories, manufacturing, and quality control – whether for small components, electronic parts, or medical products. The compact chambers can be easily integrated into existing production environments and enable fast, clean, and controlled curing with minimal energy consumption.